Automatic Milk Powder Tin Can Filling Canning Seaming Production Line

VTOPS-PFL-C

Automatic Milk Powder Filling Canning Seaming Production Line for Metal Tin Cans

Automatic milk powder filling canning line is specially designed and developed for filling milk powders in metal tins cans etc.

As we know, milk powder also known as infant formula powder, formula milk powder, powdered milk or dried baby milk). It is a manufactured dairy product made by evaporating milk to dryness. All the machines in the milk powder filling line are fabricated in full stainless steel according to food hygiene standard.

Milk powder filling by the high precision servo controlled auger filling machine , and equipment an “Online Weighing System”. During filling, the auger speed is adjusted by the weight information continuously fed back by the load cell, so that the final filled error is kept within 2 grams.

At the same time, the line is available to incorporate with other machines to form a more automated complete milk powder can filling canning production line.

Table of Contents of Milk Powder Filling Canning Line

Working Video

Firstly, let’s view the following video to see how the milk powder filling line works.

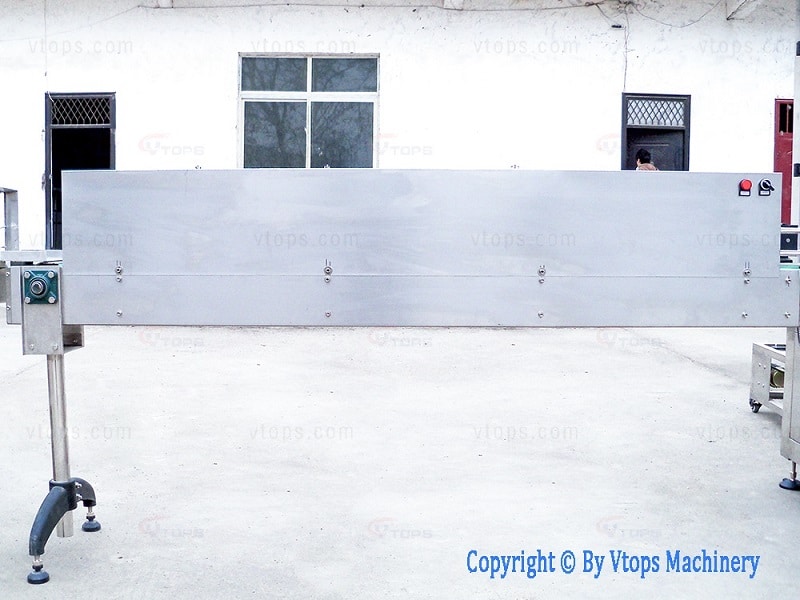

Photo

Secondly, there are two photos showing you the basic composition of a milk powder can filling line. Such as:

- Cans feeding machine rotary unscrambler;

- Empty cans cleaning machine;

- Empty cans sterilizing machine;

- High precision online weighing automatic powder filling machine;

- Automatic vacuum infill nitrogen seaming machine.

And the line is available to incorporate with other machines to form a more automated complete milk powder can filling canning production line. Such as: filled checkweigher, finished cans cleaning machine, plastic lid applicator and so on.

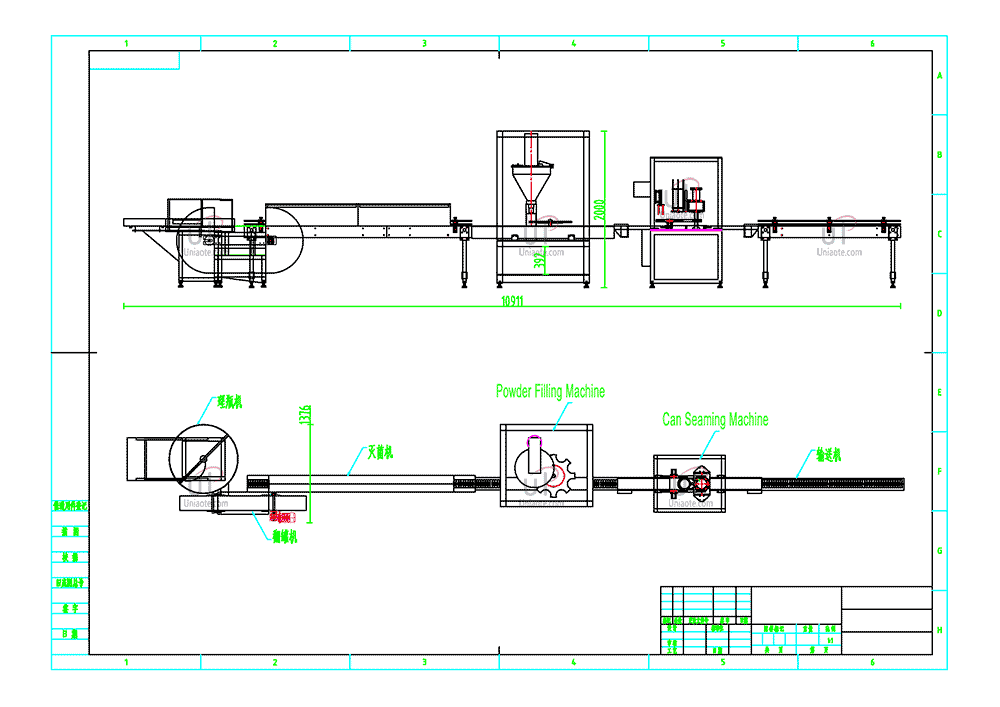

Layout Drawing

CAD layout drawing of the basic composition of a milk powder can filling line.

Detailed Description

The product description of the basic composition of a milk powder can filling line.

1. Cans Feeding Machine Rotary Unscrambler | VTOPS-F960

The Rotary Unscrambler Machine adopts frequency control rotary movement. So that the bottles or cans in the rotary tangential force sequentially into the conveyor belt. With packaging line supporting achieve the purpose of saving labor, improve work efficiency. Suitable for tin cans, glass bottles, plastic bottles, polyester bottles, and so on.

This machine component made of stainless steel, meet the GMP requirements.

2. Empty Cans Cleaning Machine | VTOPS-CM-EC

Features:

- Advanced turn cans, purging and control technology. To ensure that the tank free of impurities.

- It equipped with a degauss device. The cans opening are downwards. When the air blowing and purging the cans. The impurities are remove. Ensure that impurities such as iron can also be purge away.

- Air source produced from the machine’s own blower.

Technical Parameters:

- Maximum Speed: 60 Cans /min

- Maximum Can Size: 502 #

- Power Supply: 3P AC380V 50Hz 1.65Kw

- Dimensions: 1800 * 540 * 1173mm;

3. Empty Cans Sterilizing Machine | VTOPS-SM-EC

Features:

- The device is the best choice for sterilization empty cans for sterile workshop.

- This machine consists of two chambers. Each one chamber compose of two quartz glass UV germicidal lamps radiation. They are mounted on the upper inner side, illuminated from top to bottom. The upper stainless steel cover is easily to remove for maintenance.

Technical Parameters:

- Chain Plate Width: 152mm

- Transmission Speed: 10m / min

- Power Supply: 3P AC380V 50Hz

- Total Power: Motor 0.55Kw, Lights 0.96Kw

- Machine Weight: 200Kg

- Dimensions: 3200 * 400 * 1150mm

4. High Precision Online Weighing Automatic Powder Filling Machine | VTOPS-PSH-W

High Precision Weighing Filling Machine is suitable for all kinds of powdered, ultrafine powdered materials. Such as: milk powder, rice flour, protein powder, cocoa powder, coffee powder, chicken powder, chicken powder, additives, sugar, dyes, flavors and spices, an so on.

Features:

- The machine equipment in accordance with GMP standards for the design specifications, consistent with national food hygiene requirements.

- Chinese and English double language LCD touch screen. Simple operation. The fill weight is adjustable at any time. Working conditions can change at any time, easy operation and fast.

- Filling servo motor, with high precision, high speed, big torque, speed adjustable, good stability.

- Stirring part used by Taiwan’s production of maintenance-free gear motor: low noise, long life, maintenance-free life.

- This machine equipped with online feedback device. The fill weight is on time online feedback to control device. To ensure are demands of high-speed and high-precision.

- The filling tube outlet with dust collection devices.

- The door side-opening, convenient and practical, hopper easy cleaning, easy to replace screw attachment.

Technical Parameters:

- Measurement Methods: Screw filling weighing metering

- Container Size: Φ50-180mm H: 50-350mm (Cylindrical container)

- Measurement Range: 10-2000g (need to change the screw accessories)

- Filling Accuracy: ± (0.5-2.0) g

- Filling Speed: 8-55 cans/min

- Power: 3P 380V 50Hz 3.5Kw

- Air Pressure: 6-8kg / cm2

- Gas Consumption: 0.2m3 / min

- Machine Weight: 1000Kg

- Dimensions: 3330×1400×2400mm

5. Automatic Vacuum Infill Nitrogen Seaming Machine | VTOPS-S-VN

The Automatic Vacuum Punching Nitrogen Sealing Machine mainly for high purity canning requirements of the milk powder and protein powder. It is a new design seaming machine with three in one. It adopted electrical integration control and human-machine interface. Automatic load lids on the cans, automatic vacuum the air from cans in a closed chamber, automatic infill nitrogen, and non-pollution automatic seaming cans. The parameters are easily to set and change. It is depending on the type of round cans seaming requirements on the touch screen.

Technical Parameters:

- Production Capacity: 8 -10 cans / min

- Cans Diameter: Φ83.3 – Φ126mm

- Cans Height: 150 – 190mm

- Power: 380V 50Hz 1kw

- Machine Weight: 600Kg

- Dimensions: 1500 × 900 × 1800mm

How to contact us?

We encourage you to bring your filling needs to us. And give us the opportunity to provide you with exactly what you need.

We know that your products and business are valuable and when you choose one of our systems you are making a choice of guaranteed excellence.

Aslo, you can email us: [email protected]. My WhatsApp or WeChat ID: +86 17737712080.

[…] team has also arrived in Hamburg, Germany. Installation, commissioning and training the line of milk powder filling line export German. The entire trip will last two weeks. Although we have a wealth of export experience, […]

[…] How to packaging the infant milk powder into metal cans, and filling the Nitrogen in metal cans, please visit the article of Automatic Milk Powder Canning Line. […]

[…] 1st, it is the first day of the second half of year 2017. An automatic milk powder filling and canning line arrived in Qingdao port. It will be exported to the United States. This is a start for Uniaote […]

[…] far, it sold more than 2,000 set of powder filling and packaging equipment to domestic market. Its fully automatic powder filling canning production line for metal cans is well-known in the China […]

[…] far, it sold more than 2,000 set of powder filling and packaging equipment to domestic market. Its fully automatic powder filling canning production line for metal cans is well-known in the China […]

[…] far, it sold more than 2,000 set of powder filling and packaging equipment to domestic market. Its fully automatic powder filling canning production line for metal cans is well-known in the China […]

[…] Automatic Milk Powder Filling Canning Line […]

[…] View Enlarge Photo Image Description: CERTIFICATE OF ORIGIN Form for China-Australia Free Trade Agreement of Powder Canning Line. […]

[…] Auger powder filling canning machine is an indispensable equipment in the production of food. At present, the filling canning speed and precision of such equipment in China are generally not high. Therefore, improving the canning speed and accuracy of canned equipment has become the focus of the design of various food packaging equipment manufacturers. Whoever leads the technology in this equipment will be able to seize the opportunity in the food packaging equipment market and open the market. […]

[…] that recently. Shanxi Yashili Dairy Co., Ltd. (hereinafter referred to as Yashili Company) infant formula milk powder canning production line officially put into […]

[…] the preservation and transportation of formula milk powder has received extensive attention. Formula powdered milk cans canning has the potential to be gradually replaced lightweight plastic […]

[…] milk powder canning packing production line is a special demand of users from Vtops Machinery, and it is also a new production line developed […]

[…] Feng introduced their milk powder can filling machine and other filling-packing production lines, which are made by Vtops, to Secretary […]