A Manual Dry Powder Filling Machine Export to Australia

September 7, the cargo ship departure the Shanghai port of China. The cargo ship carrying one set of manual dry powder filling machine. It is designed and manufactured from Uniaote Machinery. It is expected to travel 23 days by sea to reach the port of Perth in Australia.

Chapter 1: A Manual Dry Powder Filling Machine Export to Australia

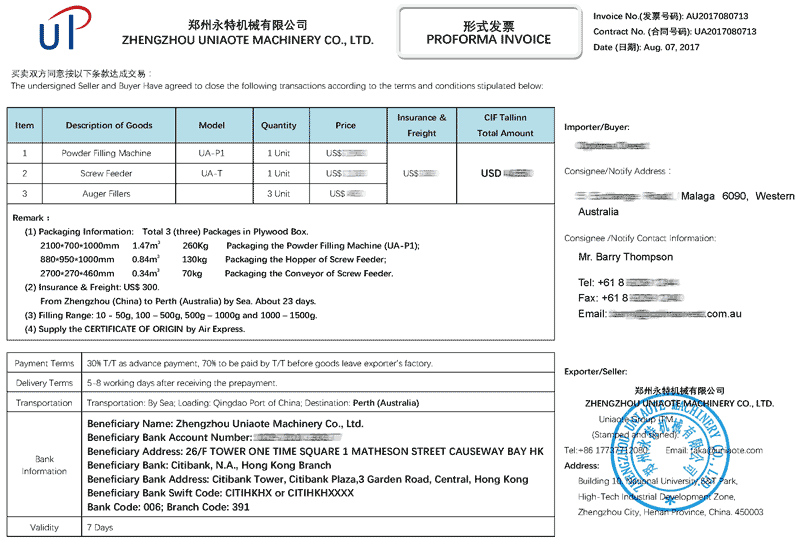

Proforma Invoice

Image Description: The Proforma Invoice of Manual Dry Powder Filling Machine

Invoice No.: AU2017080713

Contract No. : UA2017080713

Date: Aug. 07, 2017

Description of Goods:

- Manual Dry Powder Filling Machine with Auger Filler 1 Unit

- Powder Feeding Machine (Screw Conveyor) 1 Unit

- Auger Fillers and Tubes 3 Units

Before Delivery

The Photos of Packaging in Plywood Boxes:

Image Description:- Left Photo: Manual Dry Powder Filling Machine, control cabinet and scale in Plywood Box;

- Middle Photo: The hopper of screw conveyor in Plywood Box;

- Right Photo: The screw and tube of screw conveyor in Plywood Box.

Dimensions:

- Left Plywood Box: 2100*700*1000mm 1.47CBM 260Kg;

- Middle Plywood Box: 880*950*1000mm 0.84CBM 130kg;

- Right Plywood Box: 2700*270*460mm 0.34CBM 70kg.

The Photo on Delivery Area:

Marks and numbers on packages and IPPC Mark:

Image Description: Marks and numbers on packages and IPPC Mark

Image Description: Marks and numbers on packages and IPPC Mark- IPPC Mark

= The International Plant Protection Convention - Marks and numbers on packages

- TO: ****** ******

- FROM: UNIAOTE MACHINERY CO LTD

- DEST: PERTH (WESTERN AUSTRALIA)

- ITEM: POWDWE FILLING MACHINE

- C/NO.1-3/2-3/3-3

- MADE IN CHINA

Tips: What is IPPC?

The International Plant Protection Convention (IPPC) is a 1951 multilateral treaty overseen by the Food and Agriculture Organization that aims to secure coordinated, effective action to prevent and to control the introduction and spread of pests of plants and plant products.

The Convention created a governing body consisting of each party, known as the Commission on Phytosanitary Measures, which oversees the implementation of the Convention.

While the IPPC’s primary focus is on plants and plant products moving in international trade, the Convention also covers research materials, biological control organisms, germplasm banks, containment facilities, food aid, emergency aid and anything else that can act as a vector for the spread of plant pests – for example, containers, packaging materials, soil, vehicles, vessels and machinery.

What is the Delivery Terms?

- We deliver the machines within 5 working days after receiving the prepayment.

- FOB Shanghai port of China, or shipping to the main port of your country.

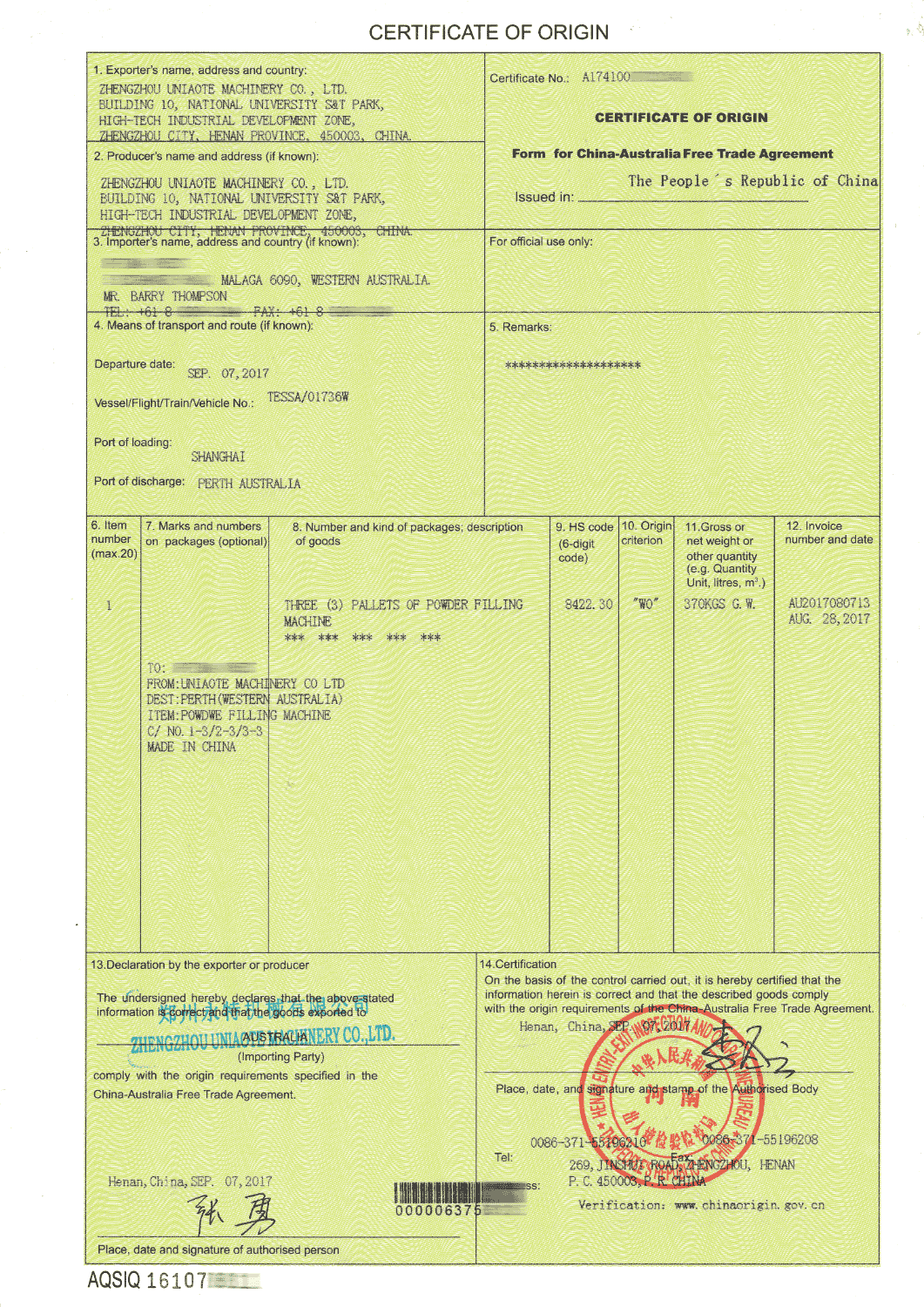

Chapter 2: CERTIFICATE

CERTIFICATE OF ORIGIN

Form for China Australia Free Trade Agreement

Issued In: The People’s Republic of China

Verification: www.chinaorigin.gov.cn

Details Information of China Australia Free Trade Agreement

- Exporter’s name, address and country:

ZHENGZHOU UNIAOTE MACHINERY CO., LTD.

BUILDING 10, NATIONAL UNIVERSITY S&T PARK, HIGH-TECH INDUSTRIAL DEVELOPMENT ZONE, ZHENGZHOU CITY, HENAN PROVINCE, 450003, CHINA. - Producer’s name and address (if known):

ZHENGZHOU UNIAOTE MACHINERY CO., LTD.

BUILDING 10, NATIONAL UNIVERSITY S&T PARK, HIGH-TECH INDUSTRIAL DEVELOPMENT ZONE, ZHENGZHOU CITY, HENAN PROVINCE, 450003, CHINA. - Importer’s name, address and country (if known):

****** ******

****** ****** ******, MALAGA 6090, WESTERN AUSTRALIA.

MR. BARRY THOMPSON

TEL: +61 8 **** ****

FAX: +61 8 **** **** - Means of transport and route (if known) :

- Departure date: SEP. 07, 2017

- Vessel/Flight/Train/Vehicle No.: TESSA/01736W

- Port of loading: SHANGHAI

- Port of discharge: PERTH AUSTRALIA

- Remarks:

****** - Item number (max. 20)

1 - Marks and numbers on packages (optional)

- TO: ****** ******

- FROM: UNIAOTE MACHINERY CO LTD

- DEST: PERTH (WESTERN AUSTRALIA)

- ITEM: POWDWE FILLING MACHINE

- C/NO.1-3/2-3/3-3

- MADE IN CHINA

- Number and kind of packages; description of goods

THREE (3) PALLETS OF POWDWE FILLING MACHINE - HS code: (6-digit code)

8422.30 - Origin criterion

“WO” - Gross or net weight or other quantity (e.g. Quantity Unit, litres, m3.)

370KGS G.W. - Invoice number and date

AU2017080713

AUG. 28, 2017 - Declaration by the exporter or producer

The undersigned hereby declares that the above-stated information is correct and that the goods exported to

AUSTRALIA

(Importing Party)

comply with the origin requirements specified in the China-Australia Free Trade Agreement

郑州永特机械有限公司 (Stamp)

ZHENGZHOU UNIAOTE MACHINERY CO., LTD. (Stamp)Henan, China, Sep.07, 2017

张勇

Place, date and signature of authorised person

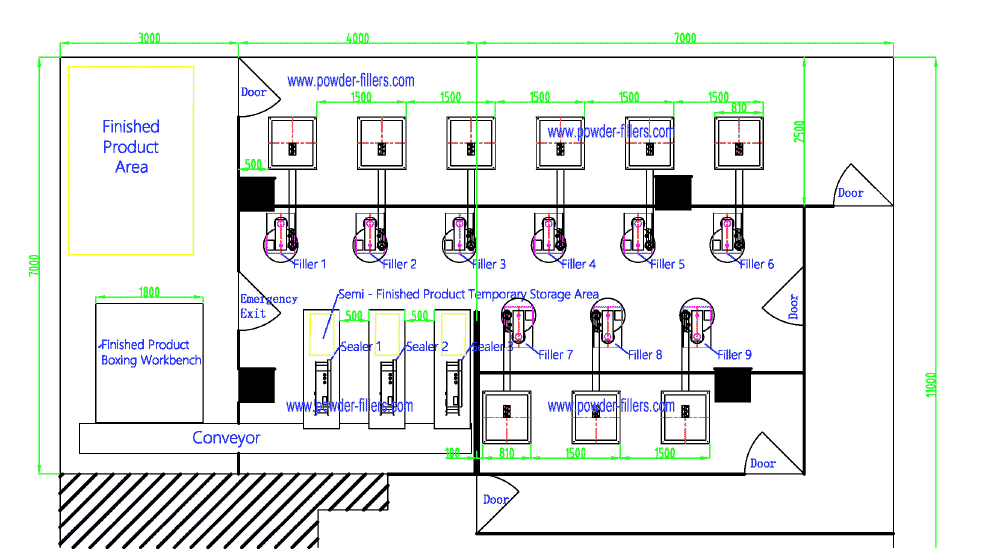

Chapter 3: Uniaote Machinery Machinery Co., Ltd.

They precisely engineered range is designed using quality components to ensure international quality standards. Further, we test our range on various quality parameters so as to deliver flawless machines to clients.

Image Description: The Factory of Uniaote Machinery Co., Ltd.

Image Description: The Factory of Uniaote Machinery Co., Ltd. Image Description: The Exhibiton of Uniaote Machinery Co., Ltd.

Image Description: The Exhibiton of Uniaote Machinery Co., Ltd.Chapter 4: Manual Dry Powder Filling Machine with Auger Filler(1 gram to 5000 grams)

Machine Type: Semi-Automatic, Manual.

Semi automatic auger powder filling machine (Manual Dry Powder Filling Machine) equipped with mechanical, electrical, optical, instrument in whole one. They are controlled by single-chip or PLC. And, they are with functions of automatic quantitative, automatic filling, automatic adjustment of measurement errors, and so on.

Classification:

According to the needs of different customers, our company developed a total of five models of 5g-5000g semi-automatic powder filling machines. They are floowing:

- UA-P1 Filling Range: 5g – 5000g

- UA-P2 Filling Range: 5g – 5000g with LCD Touch Screen & PLC & Servo Motor

- UA-P4 Filling Range: 1g – 50g

- UA-PC Filling Range: 1000g – 5000g with the features of Clamp Holding Device

Quickly Speed: Dosing by auger. Signal from light-control technology.

High precision: use the stepper motor and electronic weighing technology

4.5-5000g of materials may be on the same quantitative packing machine continuously adjustable, by adjusting the electronic keyboard and different models of blanking screw

5, Applicable to a wide range: a certain fluidity of powder-like, granular material all can be packed.

6, Suitable for bags, cans category, Bottles and other containers powder Packing

7,The error caused by the proportion of materials and materials level changed can be automatically tracked

8, Photoelectric switch control, only need manual set bags, pocket clean, easy to seal

9, The material contact parts are made of stainless steel production, easy to clean to prevent cross-contamination

10, Can be configured with feed device, for uses more easier for users

Key Specifications/Special Features:

- High Efficiency, Corrosion Resistance

- High accuracy & high efficiency

- Durable & strong

- Price competitive

Specifications:

- Range: 1 gram to 5000 grams

Need to replace the Auger Filler and Tube to guaranteed accuracy and speed; details reference the “The Diameter List of Auger Filler Tube” please! - Speed: 1200-3500 fills / hours

- Fill Control: Timer based / Sensor based

- Fill Container: Bottle, jar, pouch, can

- Accuracy: 1.0

- Hopper Volume: 50 liters

- Machine Dimensions: 690× 600×1900mm

- Power: 3P AC380 50Hz 0.9Kw (Customizable)

The Diameter List of Auger Filler Tube

- 1g-5g φ20mm – φ22mm

- 5g-10g φ20mm – φ26mm

- 10g-50g φ26mm – φ28mm

- 40g-100g φ30mm – φ34mm

- 100g-300g φ38mm – φ40mm

- 300g-500g φ40mm – φ45mm

- 500g-1000g φ50mm – φ55mm

- 1000g-5000g φ60mm – φ65mm

* The diameter of auger filler tube for reference only. Please contact our engineers for details. Thank you!

Image Description: Auger Filler Tube

Image Description: Auger Filler TubeHow does it work?

Classic Case

How to install?

Chapter 5: How to contact us?

We encourage you to bring your filling needs to us and give us the opportunity to provide you with exactly what you need.

We know that your products and business are valuable and when you choose one of our systems you are making a choice of guaranteed excellence.

Aslo, you can email us: [email protected]. My WhatsApp ID: +86 17737712080.