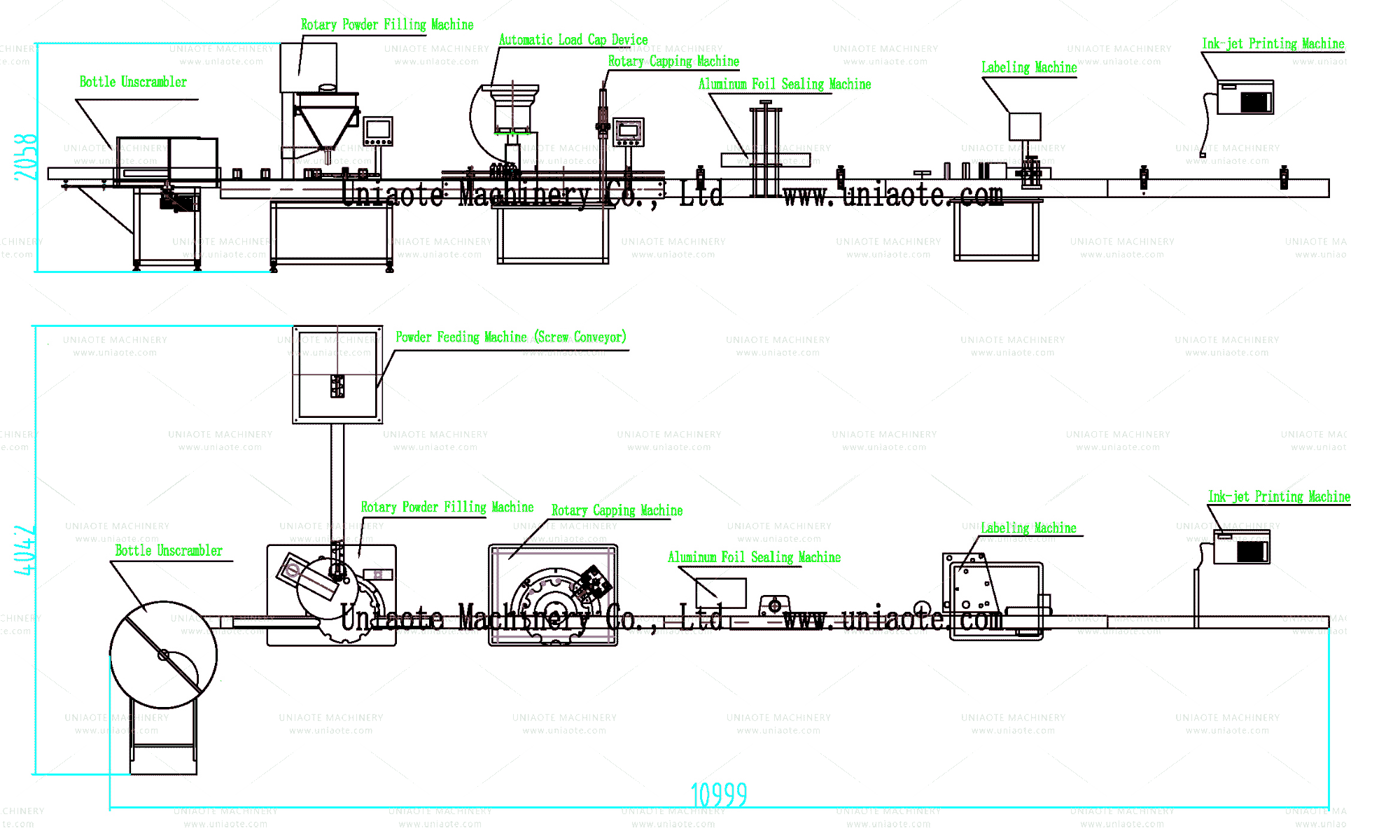

Powder Bottle Filling Capping Sealing Labeling Machine Line

Automatic Powder Filling Capping Sealing Labeling Machine Line including:

- Unscrambler Machine for Bottles (Optional)

- Powder Feeding Machine (Vibration type Screw Conveyor)

- Automaitc Powder Filling Machine

- Capping ( Sealing / Seaming ) Machine

- Aluminum Foil Sealing Machine (Optional)

- Labeling Machine

- Date/Code Printer

Unscrambler Machine for Bottles

This machine are component of stainless steel, meet the GMP requirements.

Powder Feeding Machine (Vibration type Screw Conveyor)

Vibration type Screw Feeder is suitable for all kinds of powders.

Features:

- Equipped it to the Powder packing machines and filling machines. It is controlled by the packing machine or filling machine.

- Set the switch is provided with a return material, easy to clean material

- Hopper provided with vibrators, feeding unhindered.

Technical Parameters:

- Conveying Speed: 0.5-4t/h

- Lifting Height: 1.7m; 2.3m; 2.6m; (Customizable)

- Diameter of Conveyor: φ114mm; φ159mm; (Customizable)

- Dimension: 2300×800×2100 mm

- Hopper Capacity: 100-300 Kg

- Power: AC 220/380V 50/60Hz 0.75Kw

Automaitc Powder Filling Machine

[table id=2 /]

Capping ( Sealing / Seaming ) Machine

Mainly used for a variety of round plastic, aluminum, iron screw cap capping for different shaped bottle. It is suitable for capping food, pharmaceutical, cosmetic, pesticides, cosmetics and other industries.

Features:

- Elegant appearance, smart, capping speed, high pass rate.

- Modern and unique design, mechanical torque intelligence control, and the operation and regulation is very convenient.

- A multi-purpose machine. Can be used stand-alone production, It is the ideal model to composition production line.

- With constant torque capping head, the pressure the pressure is easily adjustable.

- The structure is compact and reasonable. And it is easily link into line with other devices.

Technical Parameters:

- Capping heads: 1Head / 2 Heads

- Power: AC 220V 50Hz 1Kw

- Cap Size: 15-100mm

- Bottle Diameter: Φ35-Φ130mm

- Bottle Height: 50-320mm

- Working Speed: 10 – 60 Bottles/min

- Dimensions: 1500 × 800 × 1600mm

- Weight: 280 Kg

Aluminum Foil Sealing Machine (Optional)

Features:

- Continuous work, variable speed, stainless steel structure.

- The fifth generation of modular design, the main components imported.

- Full air-cooling, overheat alarm.

- Can be installate monitoring and excluding device for no aluminum foil cap.

Technical Parameters:

- Bottle Diameter: φ20-120mm

- Max Bottle Height: 400mm

- Cooling: Air / Water

- Sealing speed: 0-250 bottles / min

- Power:AC 220V 50/60Hz 4Kw

- Dimensions: 600 × 450 × 1310 mm

- Weight: 100kg

Labeling Machine

Technical Parameters:

- Labeling Speed: 100-250 bottles / min (Depends on the diameter bottle and label size)

- Delivery Speed: 0-23 m / min (Adjustable)

- Labeling Accuracy: ± 1mm

- Label Size: Length 15-200mm; Height 10-140mm

- Bottle Size: Diameter Φ20-Φ80mm; height ≥ 20mm

- Label Roll Inner Diameter: ≥ Φ76mm

- Label Roll Max Diameter: ≥ Φ300mm

- Powder: AC 220V 50/60Hz 200W

- Dimensions: (L) 1700 × (W) 650mm × (H) 1300mm

How to contact us?

We encourage you to bring your filling needs to us. And give us the opportunity to provide you with exactly what you need.

We know that your products and business are valuable and when you choose one of our systems you are making a choice of guaranteed excellence.

Aslo, you can email us: [email protected]. My WhatsApp ID: +86 17737712080.